Biomechanics for Medical and Assistive Device Engineering (BIOMADE) Lab

Biomechanics for Medical and Assistive Device Engineering (BIOMADE) Lab

Biomechanics for Medical and Assistive Device Engineering (BIOMADE) Lab

Faculty-In-Charge

Prof. Ganesh M. Bapatt

Lab Overview

The Biomechanics Research Group in BITS Pilani Goa Campus strives to fulfill following objectives:

- To investigate the physiological and biomechanical aspects of human gait and various musculoskeletal disorders

- To assist people with walking gait impairments and devise novel treatment strategies for musculoskeletal disorders using assistive devices and therapy

- To conduct meaningful scientific research that benefits society

- To secure recognition and funding to support students and make them competitive for their future endeavors (Industrial/Academic job, R&D, Entrepreneurship etc.)

Key Research Areas

- Assistive and Medical device design

- Prosthetics, Orthotics and Rehabilitation

- Gait Biomechanics

- Computational Musculoskeletal Biomechanicsr

- Product design and design optimization

Significant Facilities & Special Features

- First of its kind Biomechanics Research lab in the state of Goa

- Excellent facilities to design and test various assistive and medical devices

- Capabilities of simulation based testing of assistive devices

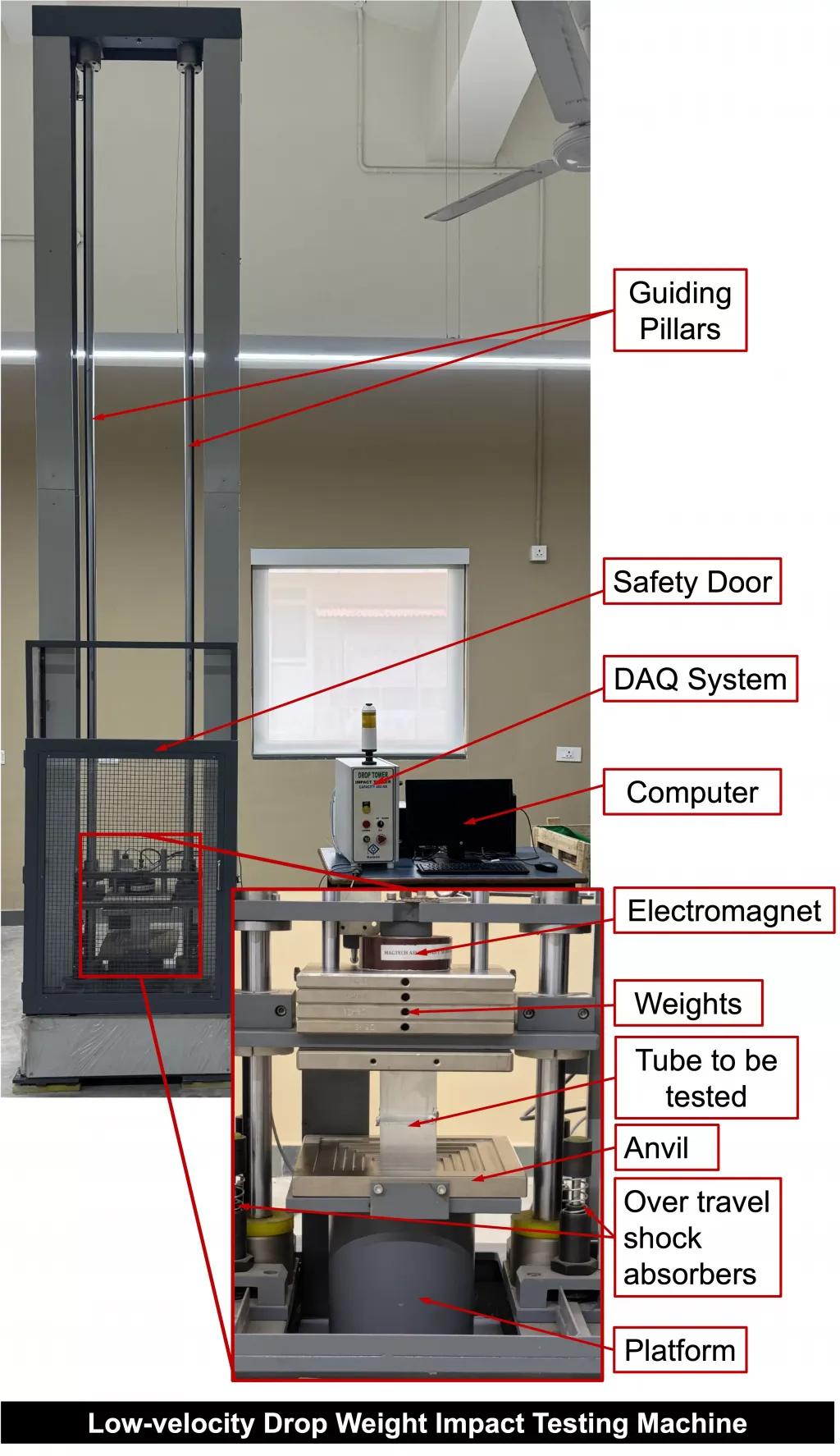

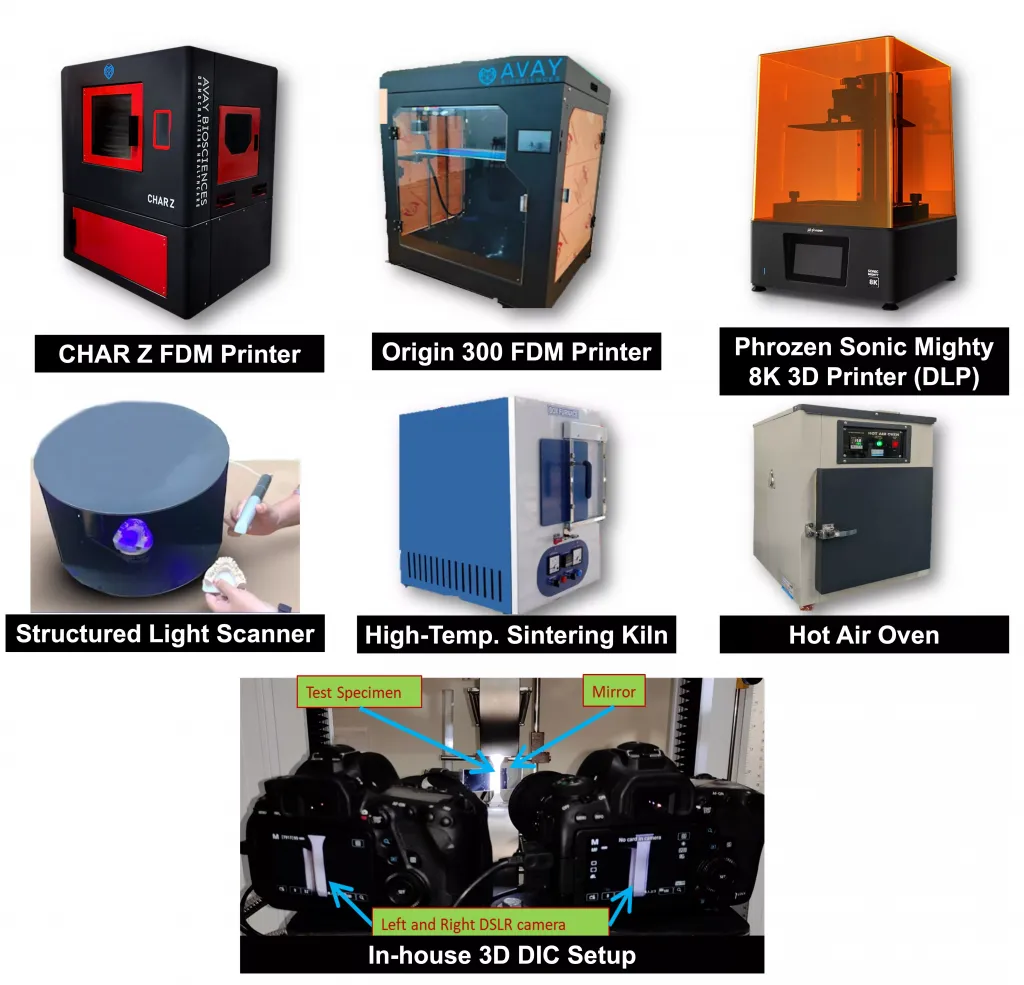

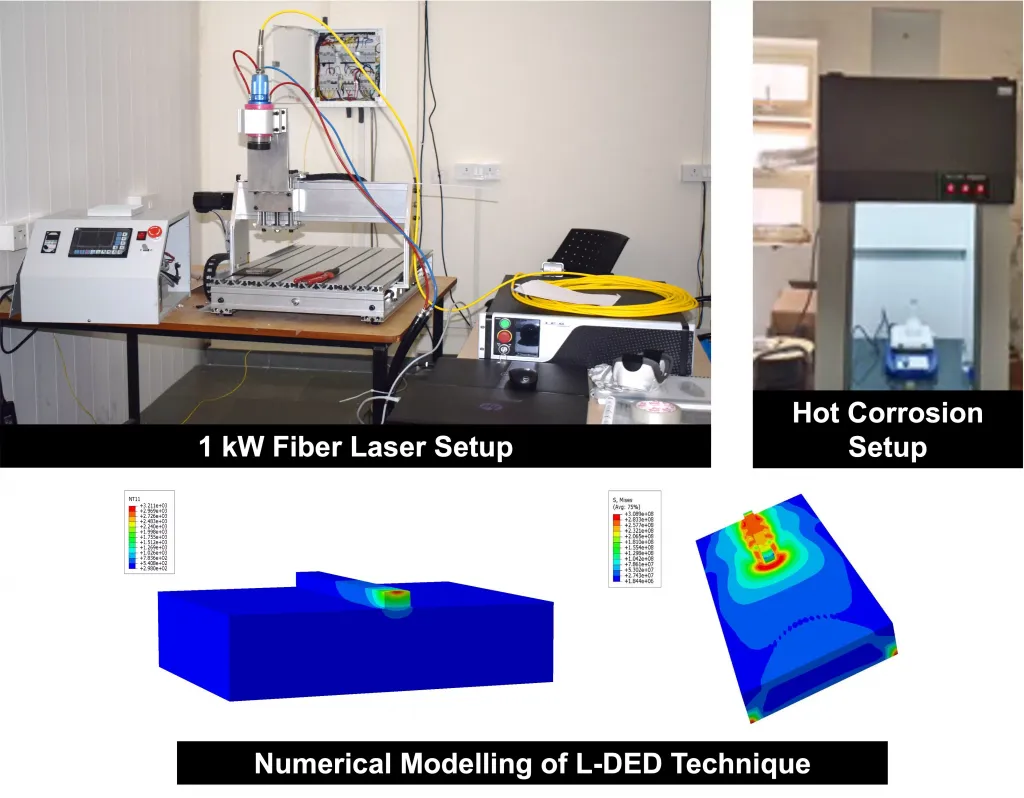

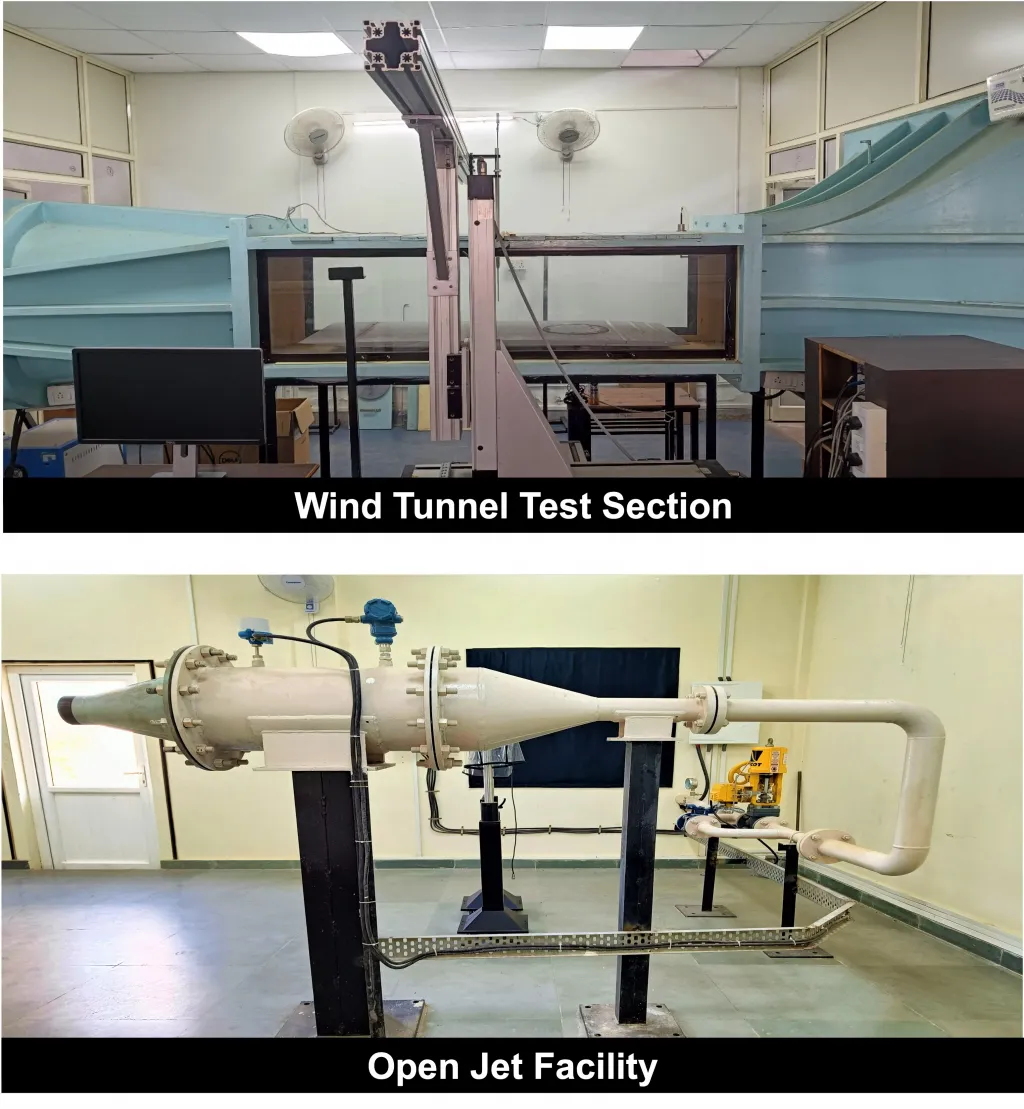

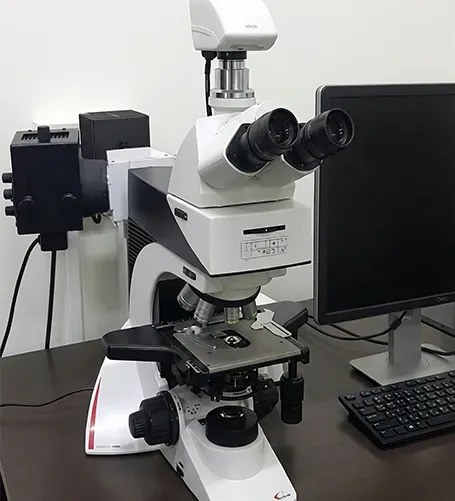

Major Equipment

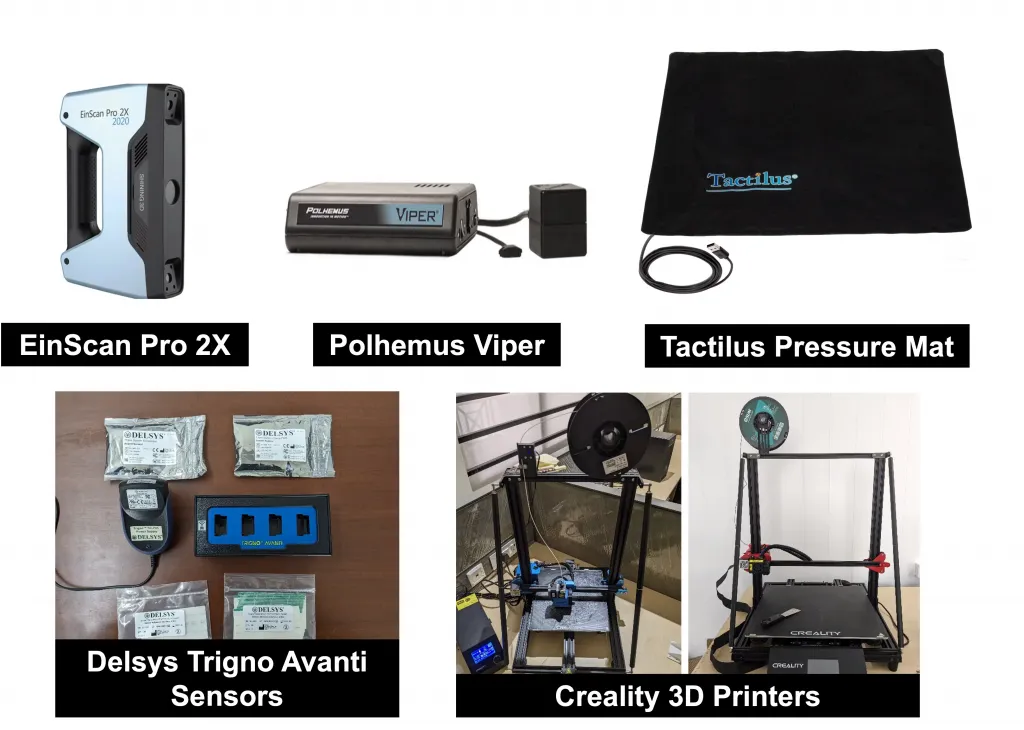

Other Facilities:

-

EinScan Pro 2X

3D Scanner -

Polhemus Viper

Motion Capture System -

Tactilus Pressure Mat

Real-time Surface Pressure Mapping -

Delsys Trigno Avanti Sensors

EMG Sensors - 3 Computational Workstations and a Laptop for Simulations and Data Collection

- Creality 3D Printers for Rapid Prototyping

Research Funding & Grants

- BITS Pilani Research Initiation Grant: 2 Lakhs

- BITS Pilani Additional Competitive Research Grant: 10 Lakhs

- Delsys DeLuca Foundation, USA grant: 2.55 Lakhs

- Department of Health Research grant: 51.96 Lakhs

- Vissco industries CSR grant: 22 Lakhs

- BITS Pilani Cross-disciplinary Research grant: 20 Lakhs

Research Funding & Grants

- BITS Pilani Research Initiation Grant: 2 Lakhs

- BITS Pilani Additional Competitive Research Grant: 10 Lakhs

- Delsys DeLuca Foundation, USA grant: 2.55 Lakhs

- Department of Health Research grant: 51.96 Lakhs

- Vissco industries CSR grant: 22 Lakhs

- BITS Pilani Cross-disciplinary Research grant: 20 Lakhs

Achievements

Patents:Total 5 patents filed, 2 design patents granted

Recognitions:

- First prize winner of Developing Countries Grant Competition-2021, organized during the 28th Congress of the International Society of Biomechanics

- Young Scientist travel grant by SERB (1.05 Lakhs) to attend international conference

Publications: Please scan the QR code for information regarding latest publications