3D Printing & Image Processing Lab

3D Printing & Image Processing Lab

Faculty-In-Charge

Prof. D. M. Kulkarni

Lab Overview

- Our laboratory is at the forefront of Additive Manufacturing (AM), specializing in the development of both metal and polymer-based 3D printing technologies.

- We explore the mechanical characterization of these materials to ensure structural integrity and optimize performance for aerospace and healthcare applications.

Key Research Areas

- Additive Manufacturing (Polymers & Metal)

- High-resolution full-field deformation measurements (DIC)

- Digital Dentistry

- Material Characterization

Significant Facilities & Special Features

- High-Precision 3D Printer & 3D Scanner

- Advanced Imaging Systems: 3D Digital Image Correlation (DIC)

- Computational Software: MATLAB R2022b, Visual Studio, ANSYS

- 3D Slicers: Ultimaker Cura, Simplify 3D, Chitubox, Mishmexer, ANSYS 3D Slicer

Major Equipment

Other Facilities:

-

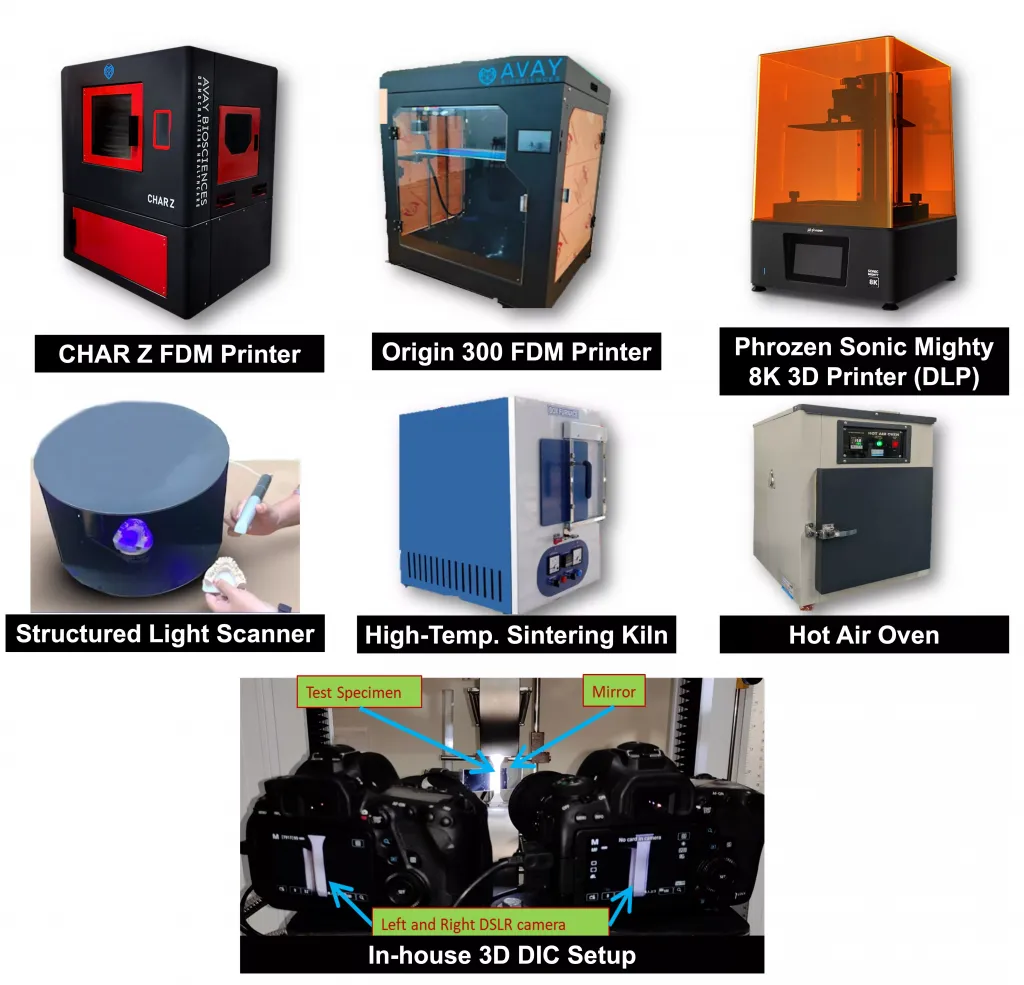

CHAR Z FDM Printer

Ultra High Performance Materials (PEEK, CF-PEEK, PAEK, PEKK)

Max Nozzle Temperature: 500°C -

Origin 300 FDM Printer

Engineering Materials (PLA, ABS, Flexible TPU, PETG, etc.)

Max Nozzle Temperature: 300°C -

Phrozen Sonic Mighty 8K 3D Printer (DLP)

High-resolution printer suitable for creating detailed prototypes, intricate models, and precise components -

Structured Light Scanner

Tabletop and handheld variant

Rapid scanning

Fully automatic -

High-Temperature Sintering Kiln

Maximum temperature: 1600°C

Programmable (TAP) control -

Hot Air Oven

Temperature range: 50–300°C

Digital temperature controller -

In-house 3D DIC Setup

Used to obtain full-field deformation measurements

-

Research Funding & Grants

- Space: INR 36.29 Lakhs

- Healthcare: INR 22.00 Lakhs

Achievements

Still have questions?

Campus

Division/Department